Vypírka exhalací odpadní vodou – Ekologická investice

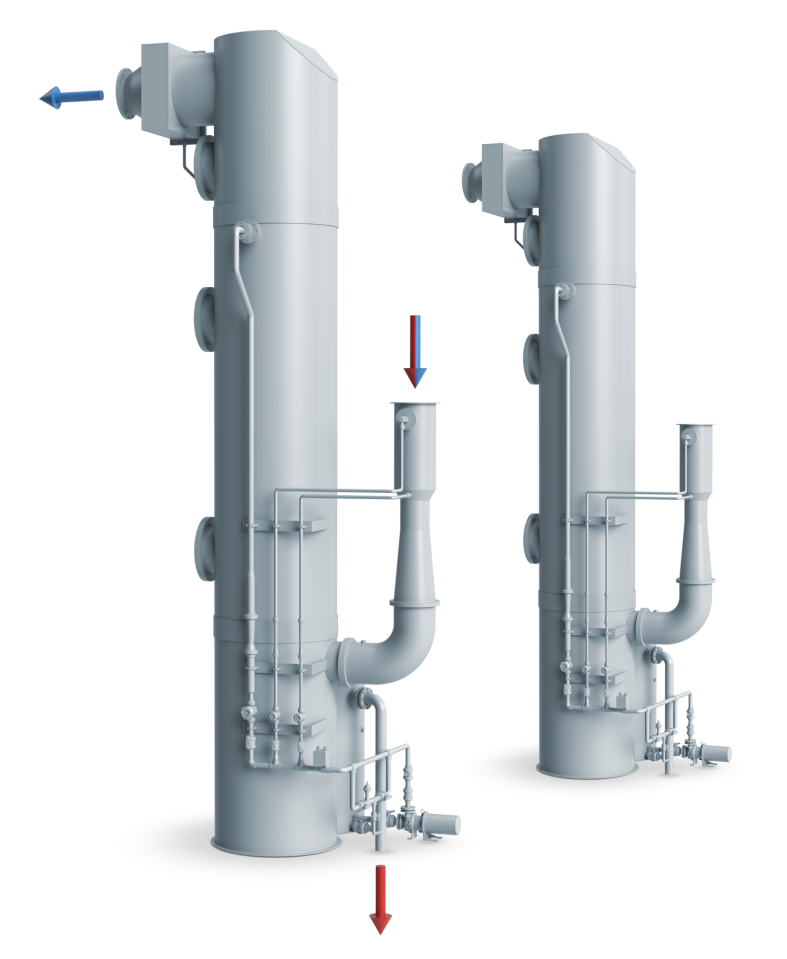

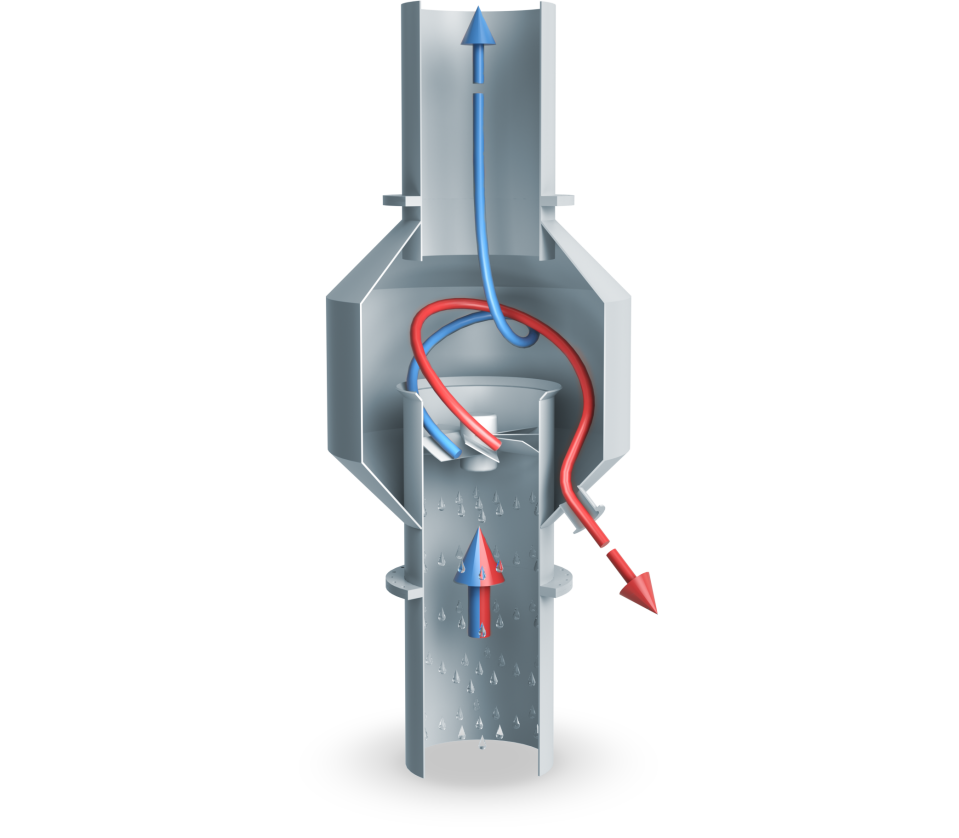

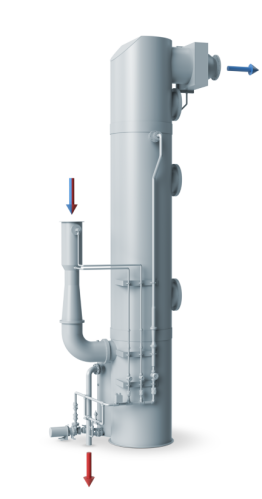

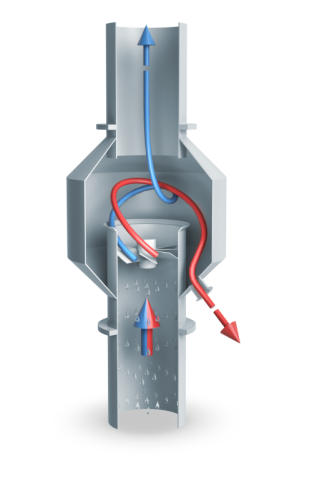

Ačkoliv Precheza Přerov splňuje všechny legislativní požadavky emisí do ovzduší, je v našem a obecném zájmu i nadále co nejvíce snižovat zbytková množství oxidů síry v odpadních plynech z výroby železitých pigmentů. Jako nejvhodnější řešení se jevila instalace mokré vypírky pomocí drahého louhu. Nakonec se podařilo efektivně využít našich vlastních odpadních vod.